Yole SystemPlus

Understand innovation to drive your progress

Breaking it Down – Yole SystemsPlus’ Mission

At Yole SystemPlus, our core purpose is to provide you with clear, exhaustive breakdowns of product manufacturing costs. We do this using an engineering-first approach that enables us to analyze a full slate of semiconductor technologies in the semiconductor industry market.

At the same time, our expert analysts deepen their holistic understanding of the arena’s key designs and processes. They in turn help you understand the latest innovations and their cost impacts, so you can confidently drive your development.

Our Foundation – A Technology-Focused Group of Experts

For over 25 years, Yole SystemPlus has been specializing in technology and cost analysis of semiconductor components and electronic systems, thanks to the tireless efforts of our highly talented and qualified people in semiconductor market research. Our complementary teams work in close collaboration day in and day out to provide you with a complete analysis of all electronic systems and components. Every step of our analyses is done internally by our experts in engineering laboratory, hardware reverse engineering, cost analysis and software development.

Our overall staff is composed of analysts with a wealth of cutting-edge skills in semiconductor and electronics technologies, compounded by years of experience in manufacturing and cost modeling. Robust expertise in sample preparation and chemical analysis allows us to deeply analyze various semiconductor structures. Likewise, our software development team puts its vast knowledge of leading-edge machine learning, leading cloud platforms and all the latest languages and database technologies to work.

Where the Magic Happens – Our Very Own Laboratory

But how are we able to conduct all of our semiconductor-level analyses in-house, giving us a precise semiconductor market overview? It so happens we maintain a state-of-the-art laboratory on our premises.

In our cutting-edge facility, we perform the following processes: package decapsulation, die delayering, cross-section, SEM pictures and materials analysis.

Our lab analysts have extensive experience in opening any type of package, executing cross-sections of fragile materials and observing specific process features – all fundamental parts of identifying process steps, which is necessary for accurate cost modeling. Throughout all of our analyses, the lab team stays in constant communication with the team of technology and cost analysts who oversee the report.

These challenging daily analyses, performed on innovative semiconductor components, are offered exclusively to our customers via the Yole SystemPlus products available in our catalogue and in our custom offers.

Materializing Continuous Improvement – Our ISO Certification

To remain on the cutting edge of our core mission, we have set up an ISO 9001 2015-certified quality management system.

This process-based approach enhances our competitiveness, optimizes our opportunities and limits risks. It is in compliance with our customers’ requirements, as well as all applicable risk and environmental management laws and regulation. Relevant indicators have been carefully identified during the implementation of our quality management system, and are evaluated through management reviews.

PRODUCTS AND SERVICES

Reports

Technology, process and cost reports are reverse costing analyses that provide technology data, manufacturing cost and accurate selling prices for semiconductor devices.

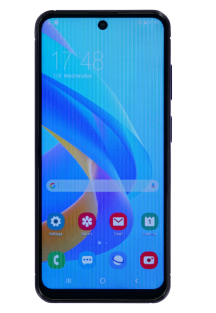

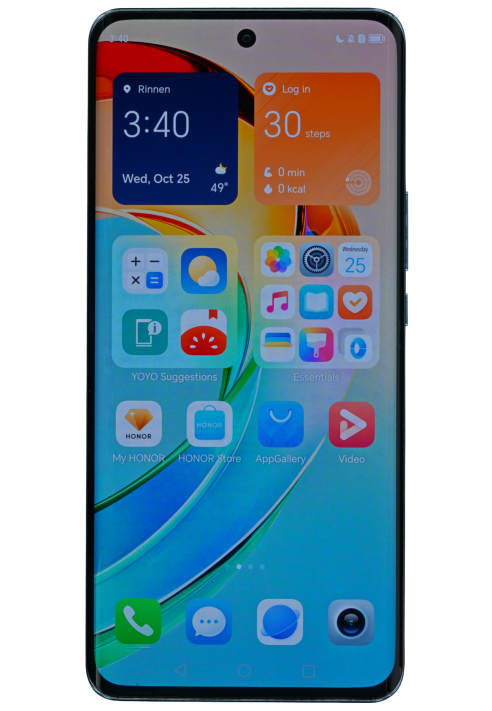

Teardown Tracks

Teardown Tracks are reverse costing of telecom, consumer and automotive electronic systems with technology and cost assessment down to the semiconductor level.

Custom Services

Our Yole SystemPlus’ experts are able to undertake custom analyses tailored to your specific needs, including electronic systems and semiconductor components reverse costing.

METHODOLOGY

Reverse Costing® consists of disassembling electronic systems and semiconductor components in order to identify the technologies it comprises. We can thus determine manufacturing processes and cost, using in-house models and tools. The result is an accurate, objective estimate of manufacturing costs and selling prices, achieved through the following steps:

- Teardown

- Reverse engineering

- Supply chain identification with economic analysis

- Manufacturing process flow modeling

- Detailed bottom-up cost and price evaluation

OUR TEAM

The strength of Yole SystemPlus is the people. The team is composed of highly qualified analysts with different competencies.

Broad and deep skills in semiconductor and electronics technologies with years of experience in manufacturing and cost modeling.

Strong know-how in sample preparation and chemical analysis to deeply analyze various semiconductor structures.

Software development team covers edge-leading machine learning, main leading cloud plateforms and latest languages and database technologies.

Romain Fraux

CEO at Yole SystemPlus

Elena Barbarini

Semiconductor Devices Department Director at Yole SystemPlus

Youssef El Gmili

Laboratory Department Director at Yole SystemPlus

Julien Keruzec

Software Department Manager at Yole SystemPlus

Jim Mielke

VP Consumer Teardowns at Yole SystemPlus

Wilfried Théron

Electronic System Department Director & Quality Manager at Yole SystemPlus

Romain Fraux

Elena Barbarini

Youssef El Gmili

Julien Keruzec

Jim Mielke

Wilfried Théron

Wilfried Théron is Senior Project Manager for Reverse Costing analyses at Yole SystemPlus, part of Yole Group. Since 1998, Wilfried is in charge of costing analyses of Electronic Systems and Integrated Circuits. He has significant experience in the modeling of the manufacturing costs of electronics systems and components. Wilfried holds a master’s degree in Microelectronics from the University of Nantes, France.

OUR GLOBAL PRESENCE

FRANCE, Nantes

At our Nantes headquarters are our teams of experts, each with their specific expertise. They work in a dedicated laboratory and teardown workshop where they perform our semiconductor analyses.

As our teams grow, so do our offices – and our precise, innovative equipment – allowing us to provide you with in-depth teardown, reverse engineering in manufacturing, technology and production cost analyses.

UNITED STATES, Austin

We have established a worldwide presence, with a team working out of Austin, Texas.

Dedicated to consumer teardowns, targetting mobile phones, wearables, smart home devices…, the team can understand most of the challenges of the new mobile systems.

Equiped with state-of-the art equipment, the team can hande custom projects in their dedicated workshop.